Feb 26, 2015

6:00 PM– 7:30 PM

Charleston Visitors Center

375 Meeting Street

Charleston, SC 29401 (map)

Continuing Education

AIA: 1.5 LU/HSW

Sc Building Council 1.5 CEUs

Certificates Provided

for all Attendees

|

|

Summary

Sealant joints are a seemingly minor component of the building envelope. However, they are often responsible for construction defects and failures—sometimes after only a couple of years. These problems often arise because of confusion as to who is responsible for designing these joints and selecting the appropriate sealant. The problem is further exacerbated because detailed design of these joints occurs is often delayed such that prior decisions make it difficult to design a satisfactory joint.

Problems with moisture intrusion are well documented. They have been a known concern for decades. Waterproofing related issues constitute the majority of post-tenancy complaints and revenue disruption. They are involved in an estimated 90% of construction-related lawsuits. Preventing these problem requires good communication between the design architect responsible for selecting joint sealants and the engineers calculating joint movement. When this conversation ignores the movement capability of the product that is expected to seal the joints, failures usually result.

Our speaker will present practical steps to avoid common mistakes that compromise effective joint sealing.

Learning Objectives

- Analyze how watertight, energy efficient, fire-rated expansion joints are the consequence of a process in which we: Design, Detail, Specify, Bid, Erect, Manufacture, & Install in 3-D.

- Be familiar with product technologies and how to apply them.

- Why it is critical to require certified performance reports in your specifications.

- Know that your next building can be a watertight structure.

Why Buildings Leak – Typical Problems

- Forces That Cause Moisture Ingress

⁃ Raindrop Momentum

⁃ Gravity

⁃ Capillary Action

⁃ Surface Tension

⁃ Air Pressure Difference

- Where Moisture Gets In

⁃ Through Cladding (Porosity of Cladding)

⁃ Improperly Sealed or Failed Joint Seals

⁃ Poorly Detailed or Executed Roof-to Wall Interface

⁃ Window Assemblies that are Poorly Designed and/or That Do Not meet ANSI Requirements for Wind Driven Rain or Hurricane Forces

⁃ Poorly Designed Vents, HVAC Units, and Other Envelope Penetrations

Joint Sealing

- Types of Joints

⁃ Structural Expansion Joints and Abutment Joints between Structures. (ex. New and Existing)

⁃ Joints at Penetrations to the Envelope (Windows, Doors, Vents, HVAC Units)

⁃ Joints between Dissimilar Materials

⁃ Joints at changes in roof lines, building shape or structural systems E:Joints in cladding panels

- Fundamental Design Issues Affecting Joint Sealing

⁃ Existence and Emphasis

⁃ Sizing & Movement

⁃ Allowable Construction Tolerances

⁃ Relationship of Calculated Movement to Movement Capability of a Product Type

⁃ Failure to Design in Other than Cross-Section

⁃ Specification of Competitive Technologies

⁃ Continuity & Communication

Joint Sealant Product Types

- Compression Seals

- Strip Seals

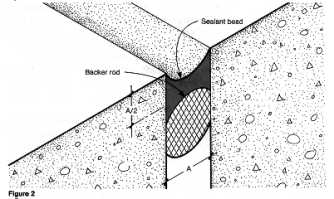

- Caulk & BackerRod

- Open-Cell Pre-compressed Foam—100% Acrylic impregnation vs Wax Saturation

- Binary Sealants--Pre-Applied & Field-Applied

Innovation & Design Versatility

- Double Sided Pre-Applied Binary Sealants

- Watertight - Fire Rated Joints achieved with a Single Installation

- Factory Fabricated Universal 90’s

- LEED Contributions including R-value, STC & OITC ratings, and longevity

Installation & Quality Management

- Function of Checklists

Biography

David Sorrells has over twenty eight years’ experience in the specification and marketing of construction products and services. He began his career in the employ of Sherman International, the largest producer of concrete and concrete products in the southeastern United States at that time. His responsibilities included quality assurance, quality control, design, testing, and sales. He then became the Marketing Director for Bhate Engineering, a regional geotechnical and materials testing engineering firm where his responsibilities included both marketing of professional engineering services and management of geotechnical, construction materials testing, and environmental engineering projects. In1995 he joined Watson Bowman Acme, an international manufacturer of expansion joints, urethane traffic membranes, and composite strengthening systems as the South Regional Sales Manager. His responsibilities included sales management, specification development, technical support, and quality control. In 2005 he joined EMSEAL as Southern Regional Manager promoting the industry’s premier line of preformed sealants and expansion joint systems. David has a Bachelor of Science from the University of Alabama and a Master’s degree in Commerce and Business Administration from Samford University. David Sorrells has over twenty eight years’ experience in the specification and marketing of construction products and services. He began his career in the employ of Sherman International, the largest producer of concrete and concrete products in the southeastern United States at that time. His responsibilities included quality assurance, quality control, design, testing, and sales. He then became the Marketing Director for Bhate Engineering, a regional geotechnical and materials testing engineering firm where his responsibilities included both marketing of professional engineering services and management of geotechnical, construction materials testing, and environmental engineering projects. In1995 he joined Watson Bowman Acme, an international manufacturer of expansion joints, urethane traffic membranes, and composite strengthening systems as the South Regional Sales Manager. His responsibilities included sales management, specification development, technical support, and quality control. In 2005 he joined EMSEAL as Southern Regional Manager promoting the industry’s premier line of preformed sealants and expansion joint systems. David has a Bachelor of Science from the University of Alabama and a Master’s degree in Commerce and Business Administration from Samford University.

|

David Sorrells has over twenty eight years’ experience in the specification and marketing of construction products and services. He began his career in the employ of Sherman International, the largest producer of concrete and concrete products in the southeastern United States at that time. His responsibilities included quality assurance, quality control, design, testing, and sales. He then became the Marketing Director for Bhate Engineering, a regional geotechnical and materials testing engineering firm where his responsibilities included both marketing of professional engineering services and management of geotechnical, construction materials testing, and environmental engineering projects. In1995 he joined Watson Bowman Acme, an international manufacturer of expansion joints, urethane traffic membranes, and composite strengthening systems as the South Regional Sales Manager. His responsibilities included sales management, specification development, technical support, and quality control. In 2005 he joined EMSEAL as Southern Regional Manager promoting the industry’s premier line of preformed sealants and expansion joint systems. David has a Bachelor of Science from the University of Alabama and a Master’s degree in Commerce and Business Administration from Samford University.

David Sorrells has over twenty eight years’ experience in the specification and marketing of construction products and services. He began his career in the employ of Sherman International, the largest producer of concrete and concrete products in the southeastern United States at that time. His responsibilities included quality assurance, quality control, design, testing, and sales. He then became the Marketing Director for Bhate Engineering, a regional geotechnical and materials testing engineering firm where his responsibilities included both marketing of professional engineering services and management of geotechnical, construction materials testing, and environmental engineering projects. In1995 he joined Watson Bowman Acme, an international manufacturer of expansion joints, urethane traffic membranes, and composite strengthening systems as the South Regional Sales Manager. His responsibilities included sales management, specification development, technical support, and quality control. In 2005 he joined EMSEAL as Southern Regional Manager promoting the industry’s premier line of preformed sealants and expansion joint systems. David has a Bachelor of Science from the University of Alabama and a Master’s degree in Commerce and Business Administration from Samford University.